Grease Fittings

www.alemite.com/pdfs/section2.pdf

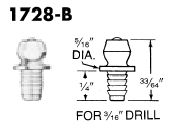

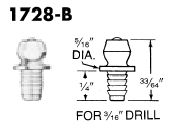

The Beech parts manual lists a grease fitting part #1645. This fitting was produced by Alemite Corp. This fitting manufactured in the 1940's and 1950's is no longer produced by Alemite Corp. However, They do have a replacement grease fitting part # 1728-B.

Available sources

2414 Ella Blvd

Houston TX. 77008

Toll Free 877-453-4333

Local 713-869-9177

FAX 713-869-9474

If you are working on one of the more common press-in Beech grease

fittings it's probable the #1645 (Alemite, new part #1728-B). Alemite does

offer a insertion extraction tool specifically for that fitting (listed

below). If using a drill bit, work your way up from a small bit and try not

to go larger than a 3/16",(4.7625mm or .1875") size bit. Otherwise you will

have to use the next larger size grease fitting. The next size up is the

Alemite #1743-B for this you'd use a 1/4" drill bit size. If you have any of

the old 1645 fittings that no longer will stay pressed in , then you most

likely will have to use the larger fitting anyway. Prepare the hole with a

1/4" bit first when using the next larger size fitting. As we already know,

the press-in fittings are really a nuisance due to the limited pressure and

abuse the will hold up to and still remain installed. Not always practical

but I like to remove any tension behind the fitting. For the landing gear, I

like to have the plane on jacks and do a partial retraction to loosen

tension of the assembly that I am trying to grease. The assembly will more

easily take the grease and not pressure up the grease gun hose. Although the

grease fittings are getting old and sometimes may contain blockage, it is

often the case of the airplane part assembly having to much pressure behind

the fitting to receive the necessary grease. The press-in grease fittings

are not designed to hold up under a high pressure environment and can

eventually be forced out of their socket by a mechanic that really puts

muscle to the handle of a grease gun. When greasing a zerk fitting,

sometimes you can't get the grease gun hose off the zerk. This is due to a

fitting or assembly that is not taking the grease and pressures up the

grease gun hose. This causes the mechanic to use force to pull the hose off.

Sometimes the grease zerk/fitting will come out of its socket and remain in

the tip of the grease gun hose. Or, sometimes a quick jerk and the grease

zerk/fitting will break-off. The grease gun hose is just doing its job, it's

suppose to grip under pressure, if you find yourself in this situation,

relieve the pressure from the grease gun before removing from zerk

Alternative ? Yes, Alemite has "Thread forming fittings" like the #3038-B

available that will take more pressure before they work their way out of the

socket. So, converting to a treaded type fitting will allow more pressure

from a grease gun and you may be able to force the grease into the assembly

without removing tension off of the assembly that is receiving the grease.

Try A&J Fittings

www.ajfittings.com/Fittings.htm

A&J Fittings

2414 Ella Blvd

Houston TX. 77008

Toll Free 877-453-4333

Local 713-869-9177

The old part #1645 that's in the Beech parts book is no longer produced by

Alemite Corp. Instead they have replaced it with the part #1728-B. Their is

also a insertion and extraction tool available part #5253-3. Available at

A&J fittings.

Their is a slight difference between the #1645 and the 1728-B

What's the difference ?

Alemite #1645 (original Beech grease fitting by Alemite)

(Overall length=30/64"), (Shank length 1/4"), (Drill dia. 3/16")

The #1728-B is 3/64" longer or .046875" longer than the #1645

Alemite #1728-B grease fitting

(Overall length=33/64"), (Shank length 1/4"), (Drill dia. 3/16")

Next oversize grease fitting

Alemite #1743-B grease fitting

(Overall length=35/64"), (Shank length 1/4"), (Drill dia. 1/4")

www.alemite.com

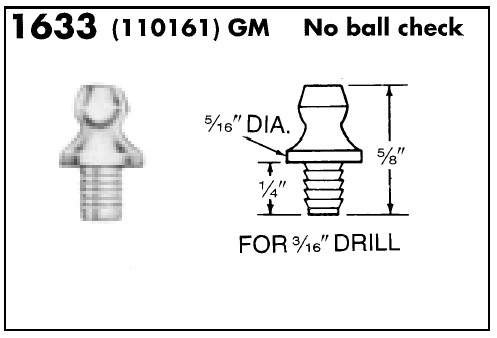

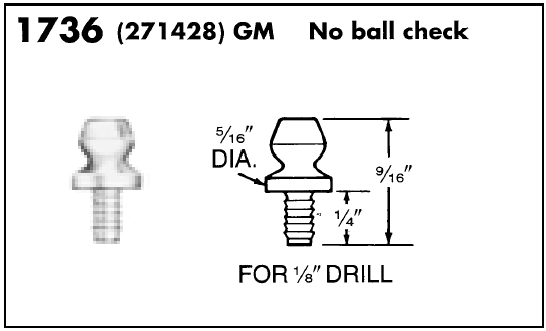

Diagrams of various fittings

www.alemite.com/pdfs/section2.pdf

Self Tapping fitting